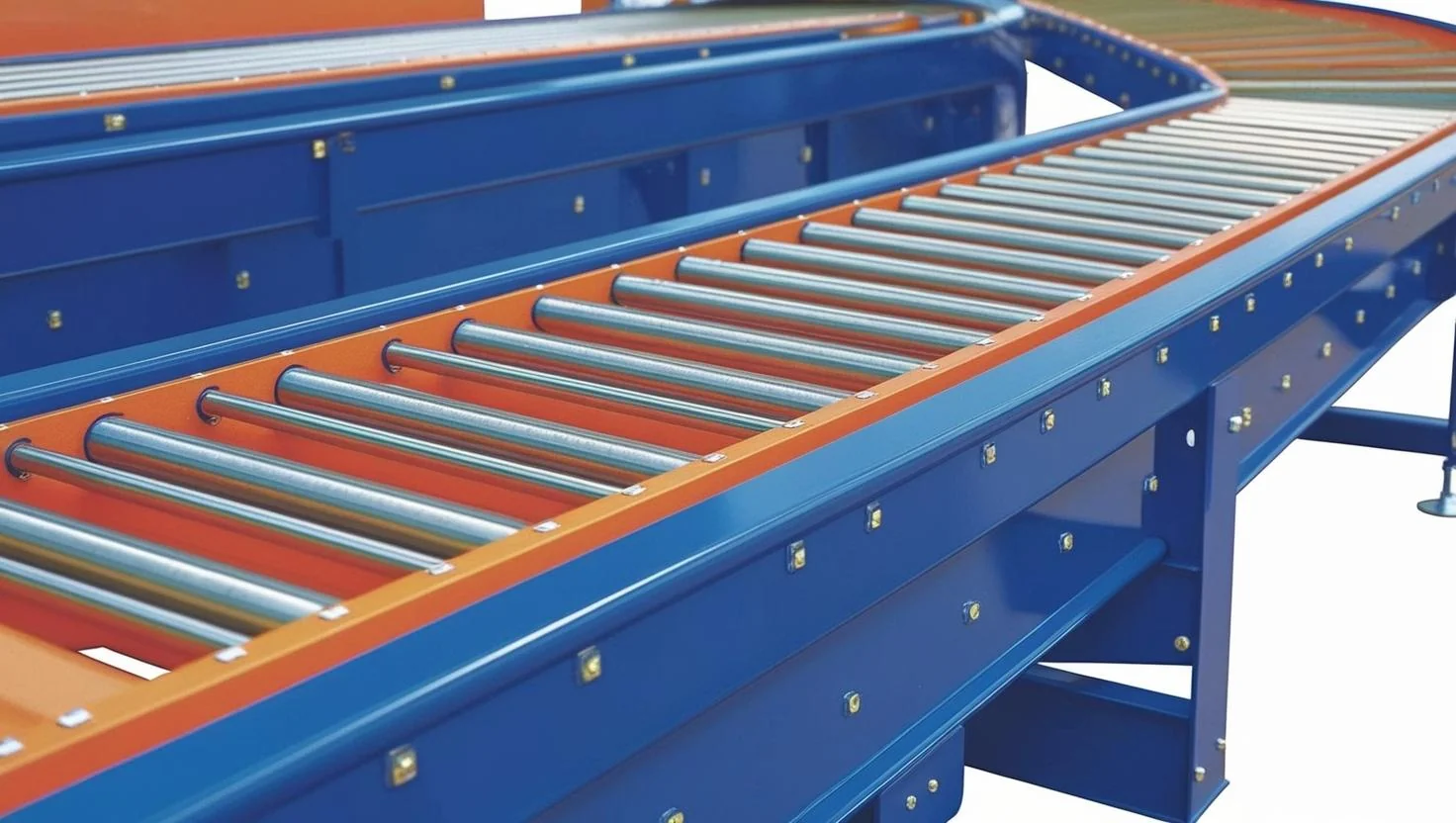

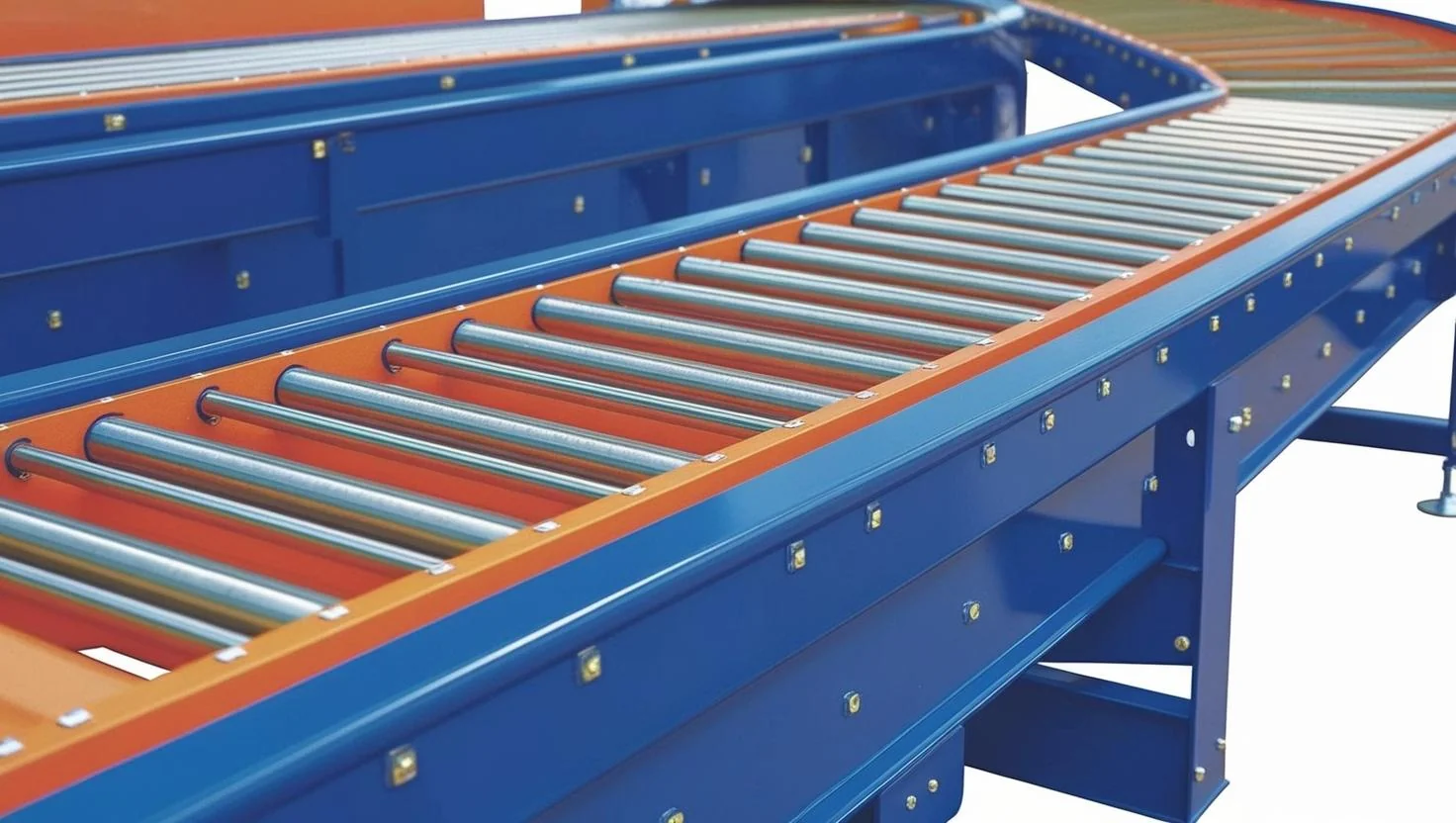

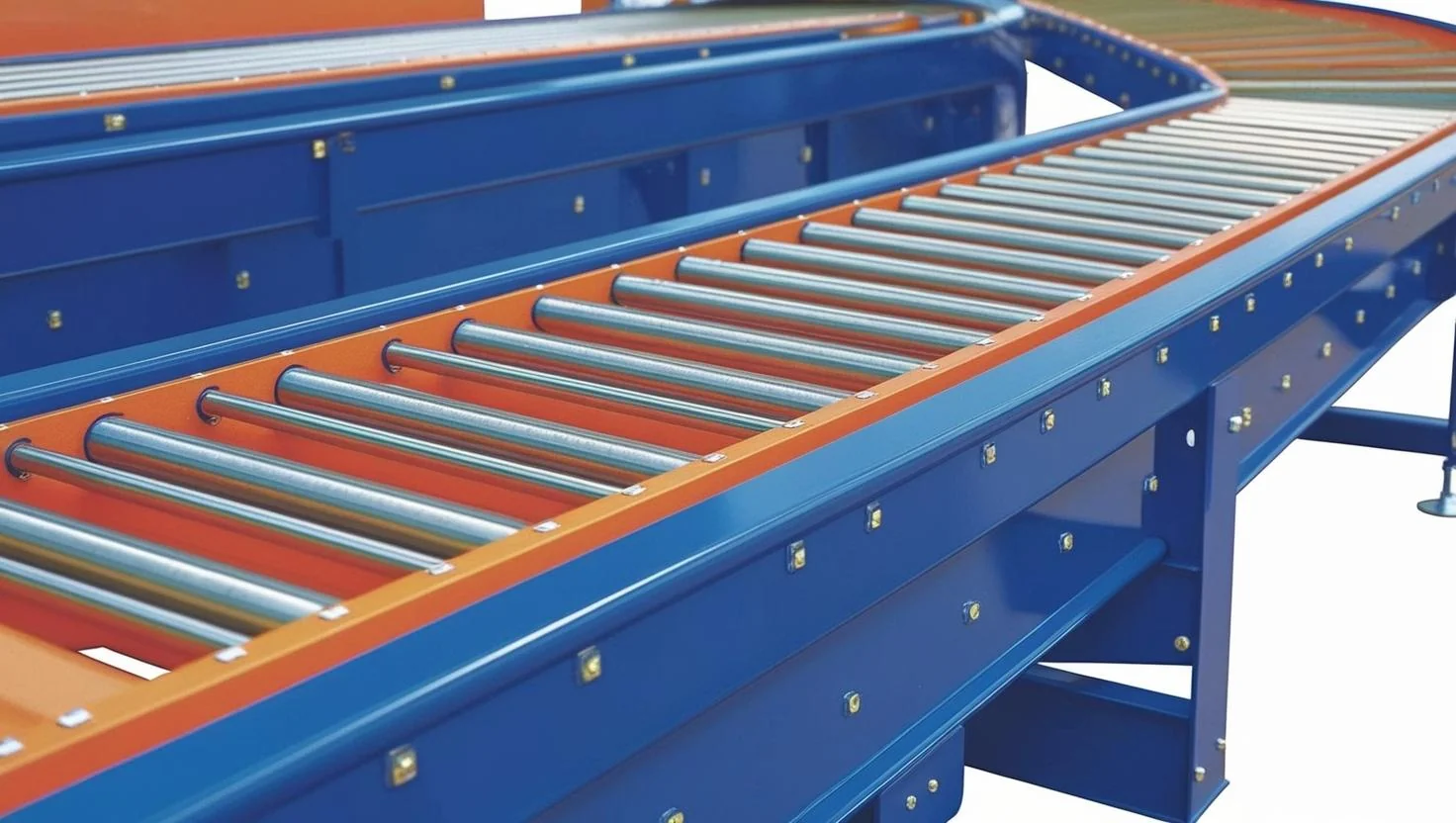

Conveyor Systems

EMITeg's Conveyor Systems represent the backbone of modern material handling operations, providing seamless, continuous movement of products throughout manufacturing facilities, warehouses, and distribution centers. Our meticulously engineered conveyor solutions optimize workflow efficiency, reduce manual handling requirements, and significantly increase throughput capacity while maintaining product integrity throughout the transport process.

What distinguishes our conveyor systems is their exceptional adaptability and precision engineering. Each system is custom-designed to address specific operational challenges, whether it's navigating complex facility layouts, accommodating varying product dimensions, or integrating with existing automation systems. This tailored approach ensures that every EMITeg conveyor solution delivers maximum operational value while minimizing installation disruption and maintenance requirements.

Product Range

- Belt Conveyors: Versatile systems ideal for transporting a wide variety of products, from small components to bulk materials

- Roller Conveyors: Efficient solutions for moving boxed or palletized goods with minimal power requirements

- Chain Conveyors: Heavy-duty systems designed for transporting large, heavy items in demanding industrial environments

- Slat Conveyors: Specialized conveyors for applications requiring product accumulation or directional changes

- Spiral Conveyors: Space-efficient vertical transport solutions connecting multiple production levels

- Modular Plastic Conveyors: Hygienic solutions for food, pharmaceutical, and clean manufacturing environments

Benefits

- Dramatically increases operational throughput and production efficiency

- Reduces labor costs and workplace injuries associated with manual material handling

- Improves product quality by minimizing handling damage

- Optimizes valuable floor space through strategic layout design

- Enhances workplace safety by reducing forklift traffic and manual lifting

- Provides real-time material flow visibility when integrated with control systems

Key Features

- Modular design architecture allowing for easy reconfiguration and future expansion

- Precision-engineered components ensuring smooth, consistent product flow

- Energy-efficient drive systems with variable speed control capabilities

- Advanced safety features including emergency stops and guard rails

- Low-friction materials and bearings for reduced operational noise

- Quick-change components for minimal maintenance downtime

- Integration capabilities with automated systems, sensors, and control platforms

- Customizable transfer points, diverters, and sorting mechanisms

Technical Specifications

- Conveyor Width: Standard widths from 300mm to 1500mm (custom dimensions available)

- Conveyor Length: Fully customizable to facility requirements, with seamless connections between sections

- Load Capacity: From 10kg/m for light-duty applications up to 100kg/m for heavy industrial use

- Operating Speed: Adjustable from 5 to 60 meters per minute with precision control

- Drive Options: Energy-efficient electric motors, pneumatic systems, or gravity-assisted solutions

- Construction Materials: Food-grade stainless steel, powder-coated carbon steel, or lightweight aluminum based on application requirements

- Belt/Surface Materials: PVC, polyurethane, modular plastic, rubber, or metal mesh options for specific product handling needs

- Control Systems: Manual operation, PLC integration, or full automation with HMI interfaces

- Accessories: Side guides, product stops, diverters, counters, scanners, and vision systems

Ideal Applications

- Manufacturing assembly lines and production cells

- Warehouse order fulfillment and distribution operations

- Packaging and end-of-line processing

- Food and beverage processing facilities

- Pharmaceutical and medical device production

- Automotive component manufacturing

- E-commerce fulfillment centers

Design & Integration Services

EMITeg provides comprehensive conveyor system design services, from initial concept development through detailed engineering and implementation. Our experienced team works closely with clients to analyze material flow requirements, identify bottlenecks, and develop optimized conveyor solutions that seamlessly integrate with existing operations. We utilize advanced 3D modeling and simulation tools to validate designs before fabrication, ensuring that each system performs exactly as expected upon installation.